Properties and Application of Hafnium Carbide

Hafnium carbide (HfC), is a chemical compound with a distinct character. It has many uses.

1. Hafnium Carbide: Its Properties

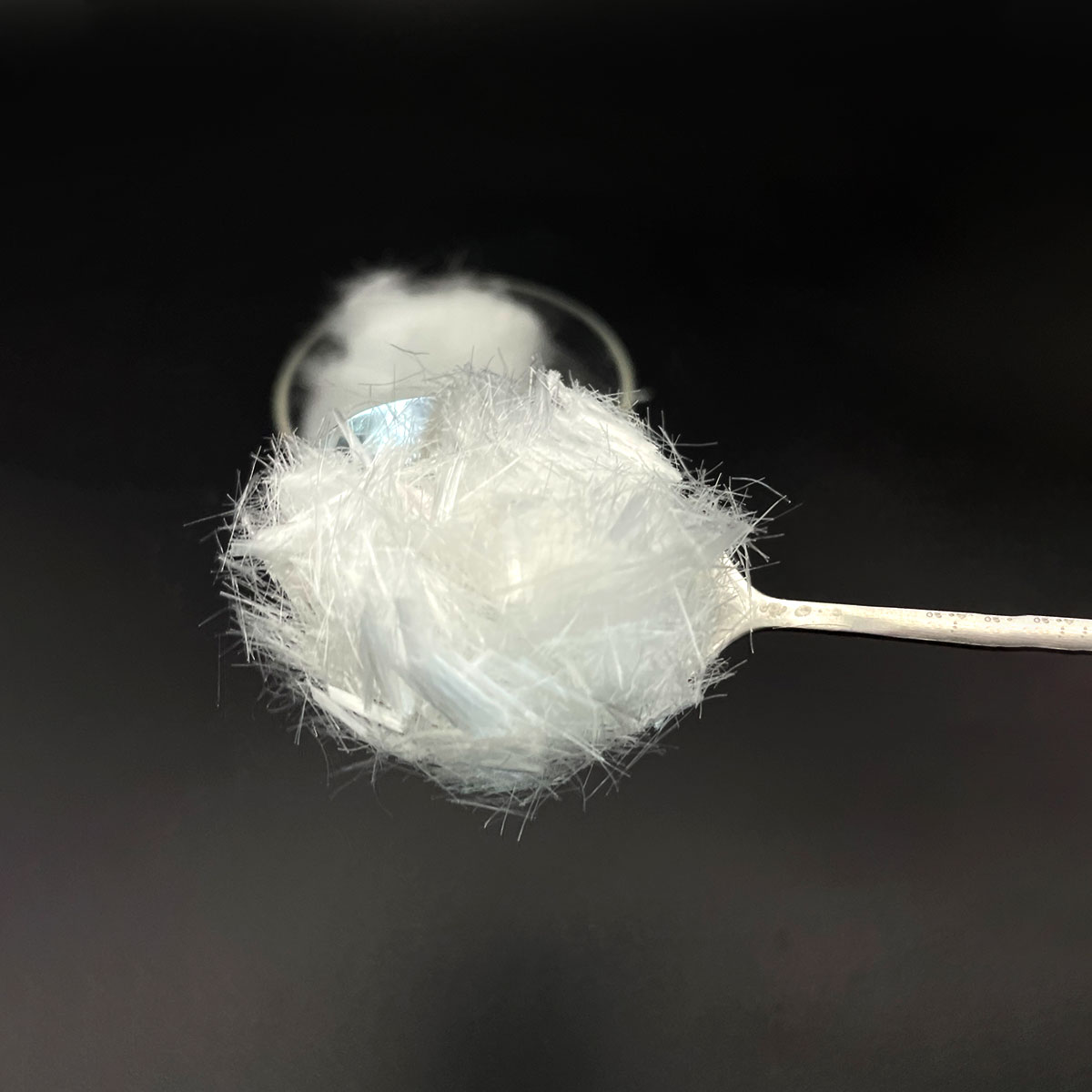

Hafnium carburide is a grayish powder that belongs in the metal carbide category. It has high melting points, good hardness and high thermal stability.

Physical property

Hafnium carburide crystals have a cubic face-centered structure and a lattice constant 0.488nm. It is a hard material with a melting temperature of 3410 degrees Celsius.

Chemical property

Hafnium carburide is chemically stable, and it is not soluble in water or acid-base solutions. It is not easily affected by high temperatures. This material is stable at high temperatures. Hafnium carburide has a high radiation resistance, and is therefore suitable for use in nuclear reactors and particle acceleraters.

2. Hafnium Carbide Application

Hafnium carbide is used widely in many industries due to its high melting points, high hardness as well as good thermal and chemical properties.

Electronic field

Hafnium carburide is widely used in electronic fields, and it’s a key component of electronic glue. Hafnium carburide can be used to increase the adhesion and conductivity in electronic paste. Hafnium can be used as an electronic device sealant, increasing the reliability and durability of electronic devices.

Catalytic field

Hafnium carburide is an excellent catalyser that can be used to catalyze countless chemical reactions. One of the most common uses is in auto exhaust treatment, which reduces harmful gas emissions. Hafnium carburide is used in a variety of fields, including hydrogen production, petrochemicals and others.

The optical field

Hafnium carbide is transparent, and it can be used for optical fibers and components. It can enhance the durability and transmission of optical components, and reduce light losses. Hafnium carbide can be used for key components such as lasers, optoelectronics devices and optical fields.

Ceramic field

Hafnium carbide can be used to improve the density and hardness of ceramic materials. It can also improve the performance of high-performance materials such as structural and high temperature ceramics. Hafnium carbide can be used to grind and coat materials.

RBOSCHCO

RBOSCHCO, a global chemical material manufacturer and supplier with more than 12 years of experience, is known for its high-quality Nanomaterials. The company export to many countries, such as USA, Canada, Europe, UAE, South Africa, Tanzania,Kenya,Egypt,Nigeria,Cameroon,Uganda,Turkey,Mexico,Azerbaijan,Belgium,Cyprus,Czech Republic, Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand, Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. KMPASS, a market leader in the nanotechnology industry, dominates this sector. Our expert team offers solutions that can help industries improve their efficiency, create value and overcome various challenges. You can send an email if you’re looking for Hafnium carburide to: sales1@rboschco.com